1. Identify development projects, understand customer needs 1. Product quality requirements; 2. Equipment production efficiency requirements; 3. Equipment working environment;

2. Analyze the product 1. Understand the production process of the product 2. Understand the dimensional requirements and incoming materials of all aspects of the product; 3. Communicate the precautions in the production process of the product with the customer; 4. The technical parameters of the place where the equipment is used;

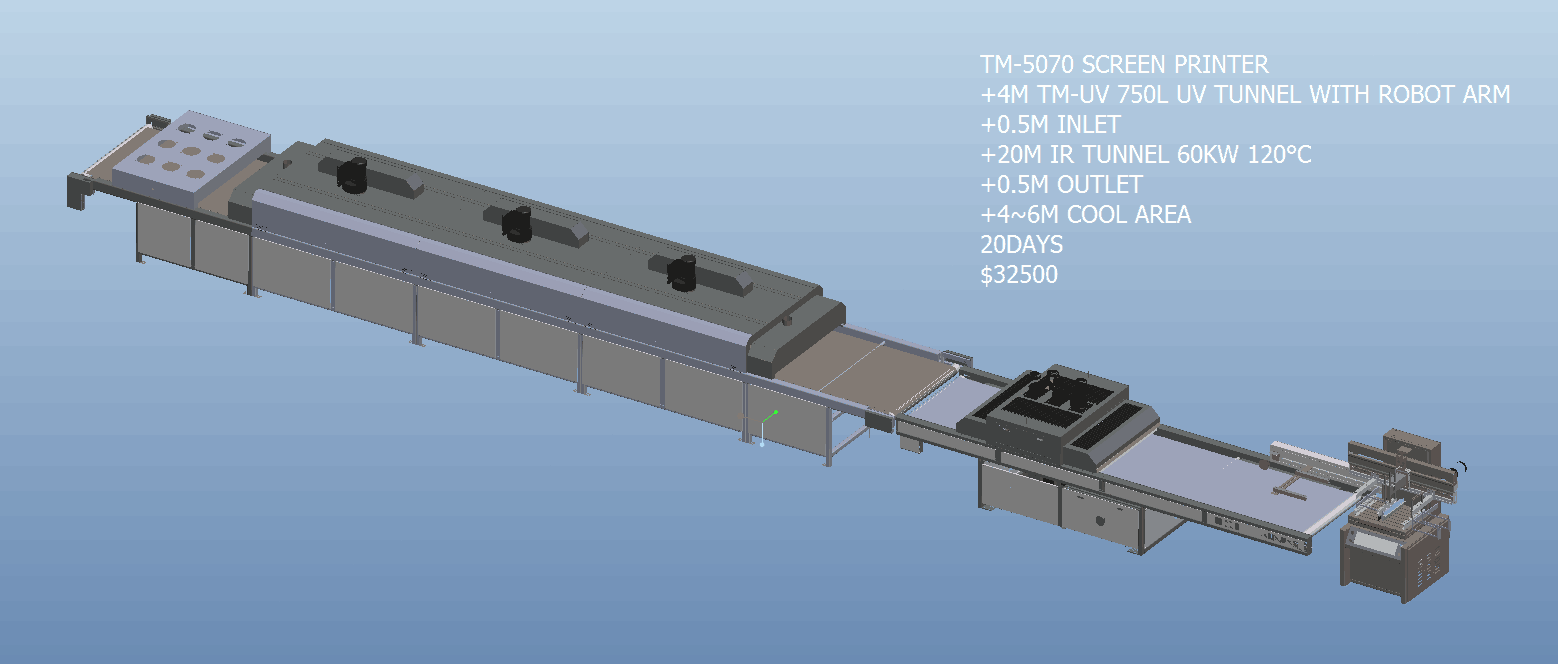

3. Formulate plans and engineers to exchange and analyze equipment plans. The plan includes: 1. Equipment schematic diagram (overall schematic diagram, partial schematic diagram); 2. Introduction of each part of the organization; 3. Operational description; 4. Equipment technical parameters;

4. The program audit consists of engineering personnel to form an audit team to review the plan. The audit includes: 1. equipment feasibility assessment; 2. equipment cost assessment; 3. equipment production efficiency assessment; 4. structural feasibility assessment of each part;

5. The rectification of the plan will rectify the problems discussed in the plan review.

6, the customer determines the design plan 1. The design plan is handed over to the customer, and the customer determines the plan according to the demand.

7. Design, development, design and development. The engineering department arranges engineers to design the mechanism, make machine assembly drawings, parts drawings (parts are marked according to national standards), select the execution components, electronic control accessories, and list the processing parts list and standard parts requisition. , action instructions.

8. Institutional audit The audit team consists of engineering personnel to review the designed drawings. The audit includes: (1) Whether the machine structure is reasonable: functional (capability and precision), stability, safety, humanization ( Convenience of operation) and appearance. (2) Whether the production efficiency of the designed machine meets the customer's needs. (3) Machine cost. (4) All parts of the organization should be simple and easy to debug and repair. (5) All parts should be as simple and easy to process as possible. (6) Whether the selection of each actuator is reasonable.

9, parts processing and standard parts procurement 1. Parts processing parts parts drawings for machine parts processing (parts must be processed in strict accordance with the parts, parts accuracy, processing technology to ensure part accuracy and parts processing technology). 2. Purchasing personnel in accordance with the standard parts list, contact the supplier for standard parts procurement inspection personnel in accordance with the parts drawing and standard parts list, to verify the dimensional accuracy of the machined parts, processing technology, standard parts of the model, installation dimensions for inspection, after passing the test Warehouse staff

10. Machine assembly (details are important) 1. The assembly department arranges personnel to carry out machine assembly and debugging. The assembly personnel collect the machined parts and standard parts from the warehouse according to the list of processed parts and the list of standard parts. 2, the assembly personnel in strict accordance with the assembly drawing, the machine assembly, all parts, the assembly of the components is correct, the activities of the moving parts are smooth, without interference, all the fasteners and joints are connected to ensure that the fastening is in place and the connection is reliable. 3. The industrial control department arranges the electrical engineer to perform machine power distribution, machine program preparation and debugging according to the operation manual.

11. Machine commissioning and assembly personnel shall perform machine commissioning according to the product engineering drawings provided by the customer. After the commissioning is completed, proof the samples and hand over the customer to determine the quality of the products.

12. Packing and shipping 1. Check all fasteners and joints to ensure fastening. In place, the connection is reliable 2. Clean the appearance of the equipment. Paste the necessary signs and signs 3. Mark the location of the split, straighten the split pipe line, reasonably disassemble the equipment 4. Necessary protection) Rust and moisture proof measures 5. Prepare equipment spare parts, operating instructions, wiring diagrams and other Technical Information.