Model No.︰large size

Brand Name︰-

Country of Origin︰China

Unit Price︰US $ 33 / pc

Minimum Order︰10 pc

Blue Printing pads advantages:

1, the ink is easy to pick up the peeling, with good results

2, silicone material and delicate, resilient, long pad life, no impurities, no particles

3, printing of a clear pattern

4, low viscosity, good fluidity

5, no shrinkage

large size Silicone Pad

More Print pad photo link:

https://doc.diytrade.com/docdvr/1963483/44987218/1460960962.pdf

http://photo.163.com/tamprinter/#m=1&aid=259243670&p=1

test report

https://doc.diytrade.com/docdvr/1963483/45829972/1477921011.pdf

Cloth printing needs flocking paste

Printing pp/PE need to flame treatment

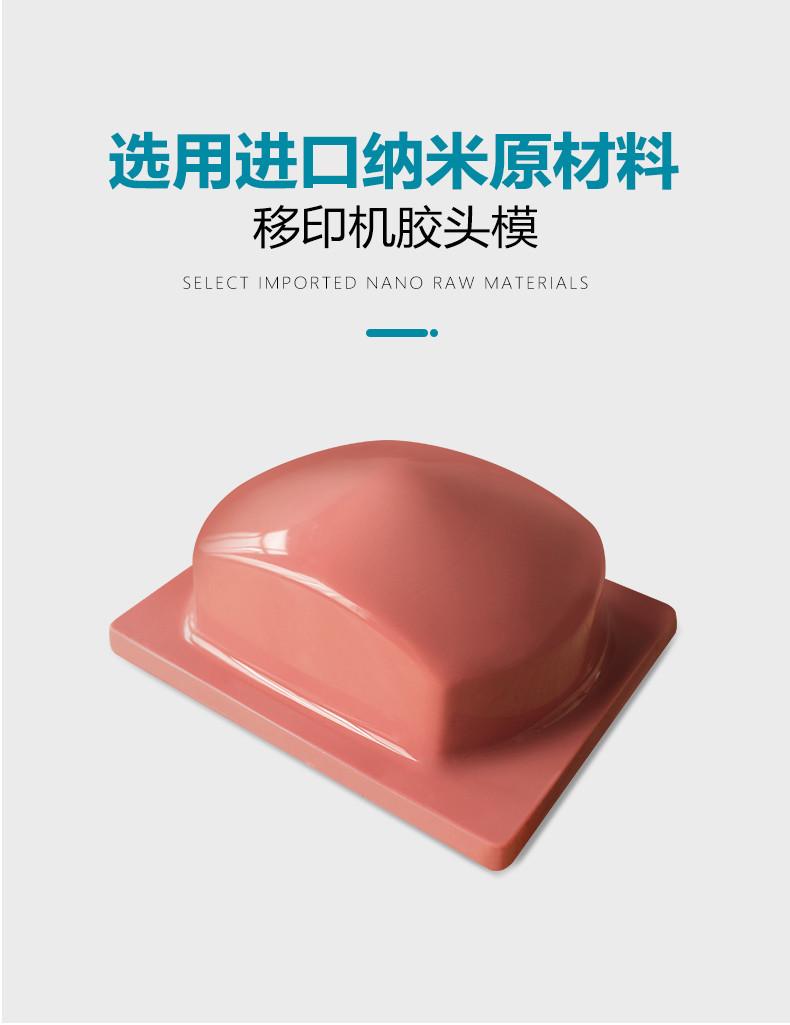

What is Rubber Pads?

PAD printing is a versatile kind of silicon rubber stamp transfer printing process. The PADS are made of silicon rubber,its function is to pick up the image from the steel plate (cliche) and then transfer it to the product of almost any convex , concave, regular ,irregular or flat surface.

PADS may be in shapes of conical, rectangular or square etc. The size, shape and image determines which Pad is the best suited.

Features:

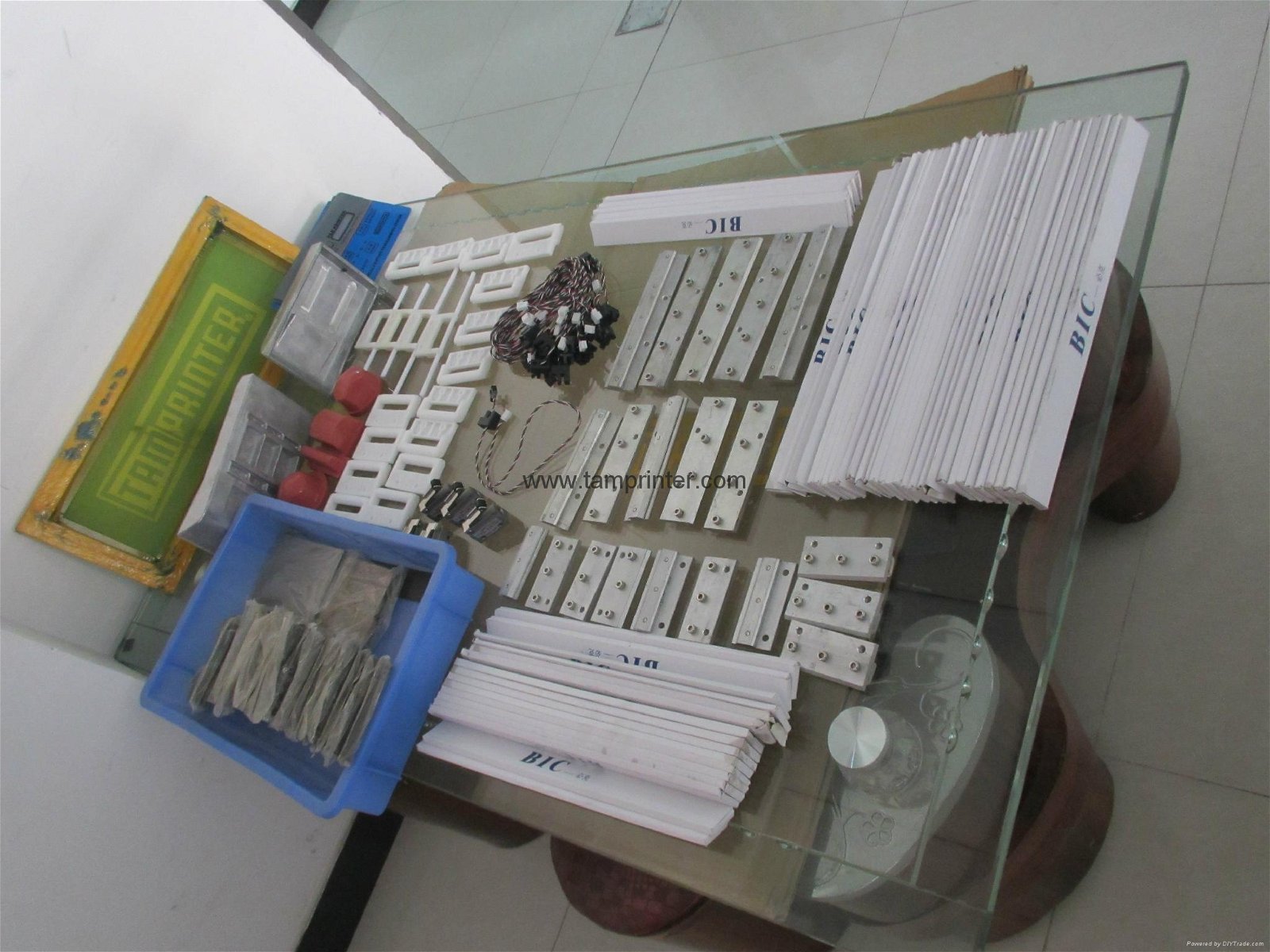

1. All pads are made of resin that import from Germany and France. 2 colors white and red, hundreds of shapes.

2. Our rubber pads have the good flexibility, the strong elasticity and the long service life which ensures high definition to flat, bend and irregular objects. Even if regarding the tiny design in the irregular superficial, it can guarantee the clear printing effect.

3. Mosstens the ink completely, it is easy to take off the ink and transfer printing, and the remaining printing ink is easy to eliminate.

4. Each kind of specification is complete, and may specially make according to the user specific requested.

5. We accept customized order with any shape.

Pad Printing Pads

Pad Shape

Pad shape can be almost anything imaginable, yet the most commonly used configurations are either round, conical, rectangle, square or “roof top” in appearance.

Please note: a print pad is only specified once the Durometer (Hardness), Color and Mounting Base is specified.

Square Shaped Silicone Print PadsRound Silicone Print Padsrectangular Silicone Print Pads

Round and Conical – Typically conical or round shaped pads are the most popular as their diameter allows them ability to print on virtually any surface be it round, flat, or irregular.

Select a standard pad from our catalog page for Round Print Pads and Conical Print Pads

Round Print Pad, red, 1.5" Diameter

Square and Rectangular – Rectangle or square pads are more often used when solely printing lines of copy or graphics on flat surfaces.

-> See catalog page Square Print Pads and Rectangular Print Pads

Square shaped silicone print pad long life rubber

Roof Top – generally used when a pad must be forced within a narrow geometric area such as the parting line of a semiconductor strip.

-> See catalog page Roof Top Pads and Elongated Roof Top Pads

Roof top shaped rectangular print pad

Special pad shapes or custom pads should only be utilized if and only if the common shapes fail. Custom pads are usually more expensive than standard shapes.

See our catalog for examples of Custom Print Pads

Print Blanket – generally used like rectangular print pads hover build on metal shim as base

– See catalog page Print Blankets

Silicone Print Blankets

Rotary Print Pads or Print Rollers – used from round items where the print needs to cover more that a common print pad can print.

-> See catalog Rotary Print Pads

Silicone Print Pad - Cutom

View and print our complete Print Pad Catalog (PDF Format)

Pad Durometer / Hardness

In addition to the shape, the durometer (hardness) of the print pad plays an equally important role.

Remember, as a rule of thumb: ” The higher the angle, the harder the durometer, the better the print.” However, substrate structure, tooling layout, and a many other factors may not allow the use of a hard-pointed pad. To deal with these obstacles, choose lower angle pads. And the durometer /hardness of the pad is adjustable. AccuPad can manufacture pads in the range of 20-80 Shore OO or anywhere in between with a plus or minus 3 range consistently.

By special request, Tamprinter will design and produce a “dual durometer” print pad which has two different durometers in one pad or even a hollow pad for those extremely difficult applications.

Pad Color

Print Pads in many colors possibleWe also have a wide range of colors if color is your preference, and any durometer can be any color:

Blue, Gray, Pink, Lime, Green, Yellow, Orange

Lavender, Bright Red, Dark Green, Beige/White, Red/Mauve/Rust

Pad Mounting

All pads are manufactured on bases to match virtually any pad printing equipment.

Any customer specified base is possible:

Base material: ply wood, aluminum, various plastic materials

Base shape: round, square, rectangular and customer specified

Base mounting: threaded at any size, for example: 1/4″x20, 5/16″x18, 3/8″x16, M6, M8

Print blankets are molded to steel or brass shims at 0.01″ or 0.25 mm thickness and in dimensions specified by the customer.

When ordering a Pad, please indicate which type mounting base you require. If unsure, please feel free to call or email us and we can help to determine the proper base and mounting requirements.

Payment Terms︰ TT/Western Union

![]()

![]()

![]()

![]()

![]()

![]()